For painting never had any of my gutters peel i washed them with tsp then lq thinner followed by an etch with some diluted muriatic acid and water washed.

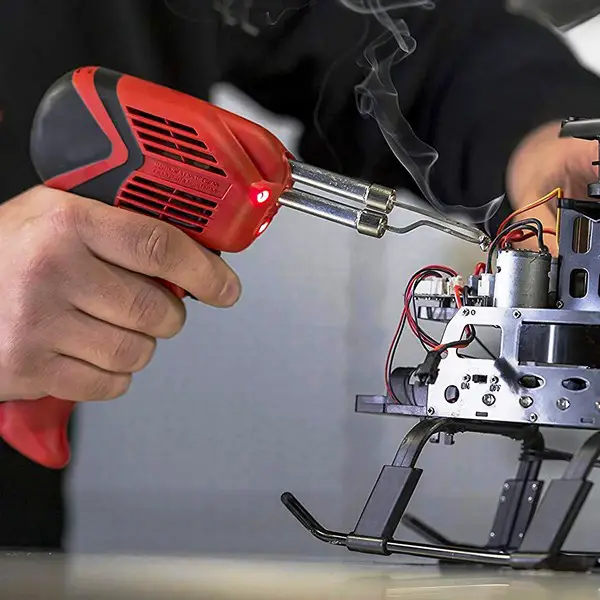

How to solder gutters with heat gun.

This should take no longer than a minute.

Https goo gl c78rza as well as all kinds of other diy jobs a heat gun is very handy for soldering copper pipes.

It takes a bit of skill when soldering copper gutters.

When your bolt is hot enough to easily melt and take the lead place it on the piece to heat that and feed the led slowly keeping the bolt on the overlap.

Brush the area to be soldered with spirits of salts hydrochloric acid.

When it comes to installing copper gutters you will have to solder them together including the drop outlets and end caps on site.

These gutters are attached to the fascia board using fascia brackets.

2 soldering metal gutters.

The other problem is installing a long section of gutter after you solder it together its like trying to string up a length of pasta takes several guys to keep it from twisting and kinking.

It s most suitable for working with soft s.

Since roofing does not require as much accuracy as working with tiny components the usual soldering iron for roofing has a broad tip that can heat very quickly and is often assisted by gas to maintain its heat in windy conditions.

Metal gutters for homes are held together by soldering.

The iron takes longer to heat up but is less expensive.

The solder should run underneath the overlap.

Copper gutters are half circle channels found below the roof line.

To add a single new component to the board first place some solder paste on the component.

A pencil styled iron above right and a soldering gun.

Then fire the heat gun onto the solder paste holding the component with tweezers or another tool that won t catch fire until it becomes shiny.

A pistol style gun with variable controls which is safer than a single temperature wand style one.