Unlike welding soldering allows the user to bind small pieces of metal together and is commonly used in the manufacture of circuit boards.

How to solder galvanized steel gutters.

And steel expands and contracts less than aluminum which means less stress on sealed joints.

Steel gutter components are zinc coated and carry 20 to 25 year corrosion warranties and up to 40 year paint warranties.

Soldering with regards to roofing is the process of joining two pieces of metal together using solder to create a leak proof seam.

When you get started soldering it may seem difficult to fill the joints properly while maintaining a degree of professionalism.

Turn the tool slowly to coat the tip in a thin layer of solder.

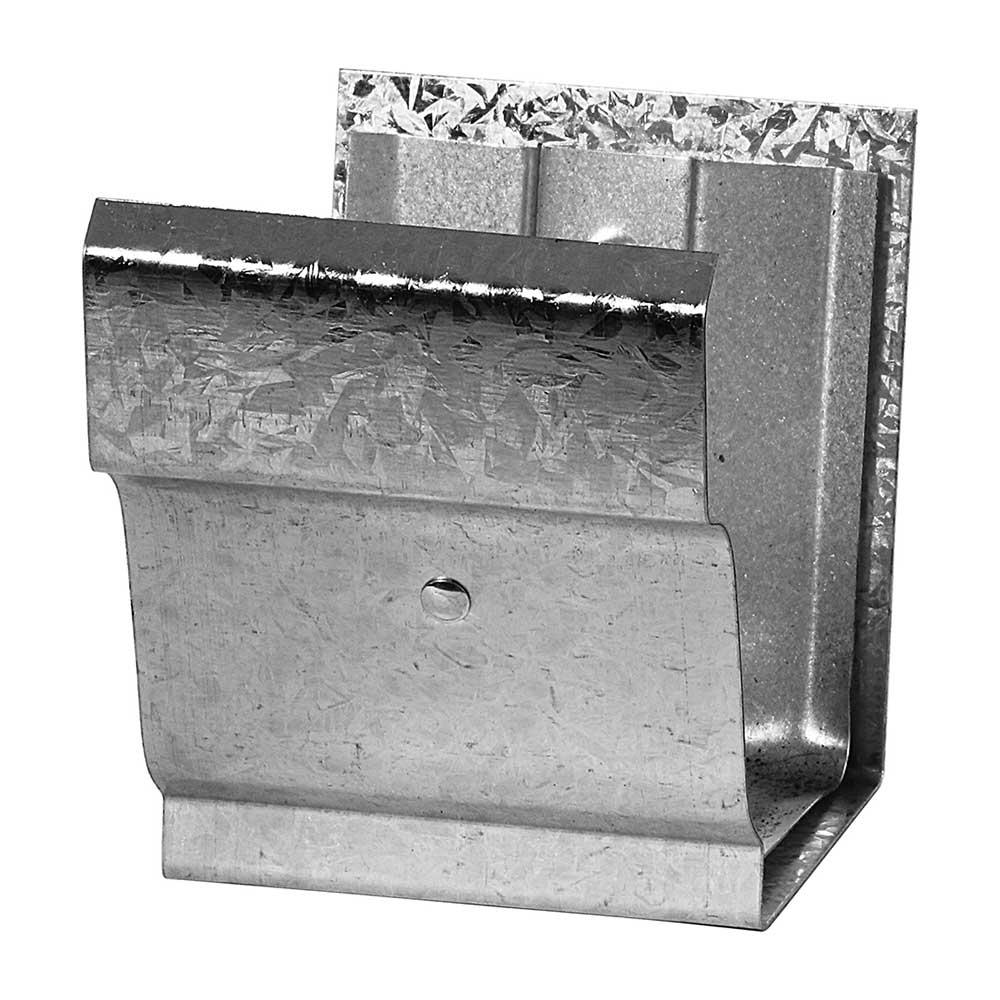

Galvanized gutters are made from hot dip steel and have been effectively used for more than 150 years.

Galvanized gutters particularly the zinc coating on the gutter should hold up for decades before there are any signs of corrosion.

They can be soldered at the joints or pop riveted and sealed with a seam sealer.

As for the price steel costs about 15 more than aluminum.

Super alloy 1 can easily solder galvanized steel plates together.

I am putting galv sheeting on a garden work bench with l flashing on the edges.

Step 6 hold the soldering tool against the galvanized steel where you want to apply the solder.

Galvanized steel gutters will hold up in extreme cold and hot temperatures and are particularly popular in areas with snow and ice.

Hi ted the first writer and i are interested in knowing how to solder galvanized materials like rain gutters.

Super alloy 1 has a very low melting point which prevents the galvanized coating from burni.

Secure the rest of the hangers with 2 in galvanized nails or screws.